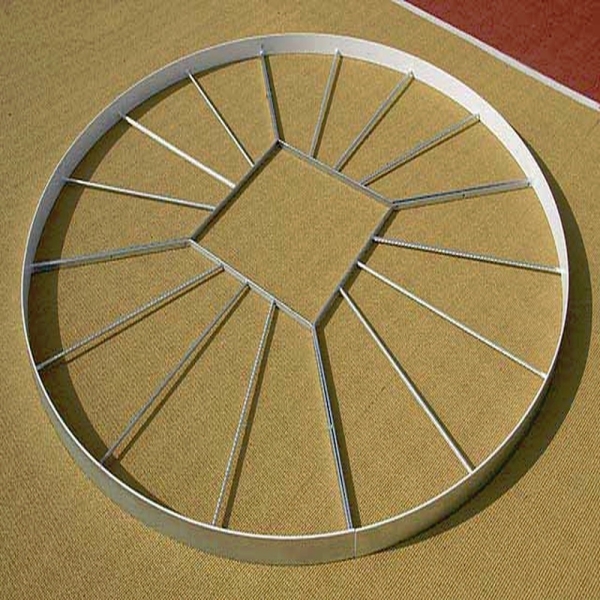

Cast wheel

Equipment to challenge

Throwingwheels are indispensable elements of sports infrastructure, providing optimal conditions for athletic competitions, including the discus throw. Robust construction, precise workmanship in accordance with WA international standards and advanced production technologies make the offered products reliable and of the highest quality, so they will meet the requirements of even the most demanding users.A solid foundation to reach the podium - why throwing wheels?

More useful information can be found at the bottom of the page.-

DC-250 discus throwing wheel

2,019.35 PLN Tax inc.1,641.75 PLN NetCatalog no: 12-20029

Availability: Made to order

Helpful information about castor wheels in a nutshell

1. technical specifications and materials

Material and manufacturing processes- Throwing wheels are usually manufactured from galvanized steel, which provides them with excellent resistance to corrosion and mechanical damage. The electroplating process involves coating the steel surface with a thin layer of zinc using a prior electrolytic bath containing zinc compounds, which acts as a protective barrier against moisture and weathering. This type of coating not only ensures the longevity of the product, but also minimizes the need for maintenance and repairs in harsh outdoor conditions. Steel used in the manufacture of wheels must meet strict strength standards, which guarantees stability and safety of use.

Dimensions and specifications

- The standard diameter of the castor wheel is 2500 mm, which is in accordance with WA guidelines. This specification ensures that the wheels can be used in official competitions, and meet the regulation requirements for size and geometry. The wheels typically consist of four main steel segments, which are connected to each other by precisely positioned bolts. The use of eight bolts in the structure not only ensures the stability of the entire structure, but also makes it easy to assemble and disassemble. Each segment is designed to fit perfectly into the others, eliminating the risk of misalignment and providing an even throwing surface.

Coatings, finishes and certifications

- The inner surface of the wheel is often coated with a special white paint, which primarily provides an additional layer of protection, enhancing the anti-corrosion properties of the galvanized steel. This paint is resistant to abrasion and UV rays, ensuring a long-lasting aesthetic appearance and functionality even after many years of intensive use.

- Each throwing wheel is manufactured in accordance with international standards and is certified by World Athletics (WA), which confirms its compliance with the technical requirements set by the athletics federation. Such certification is essential for equipment used in international competitions, as it ensures that the product meets all the necessary criteria for workmanship and safety. Certified throwing wheels can be used in both national and international competitions, making them a versatile choice for clubs and sports event organizers around the world.

- Ultimately, thanks to the advanced design and use of high-quality materials, the throwing wheels are not only durable, but also extremely functional, providing athletes with the ideal conditions for top performance.

2 Application and functionality

- Throwing wheels are an indispensable part of the equipment of any athletics stadium. In the case of the discus and hammer throw, the wheel serves as a launching area from which the athlete makes rotational movements to gain sufficient speed and momentum before the movement. The surface of the wheel must be smooth and non-slip, which provides the athlete with stability and control during the rotation.Functionality, safety and adaptation

- The functionality of throwing wheels is based on their ability to provide athletes with optimal conditions for training and competition. The wheel's stable construction and proper finish eliminate the risk of slipping, which is crucial for the safety of athletes performing complex and dynamic movements. The inner surface of the wheel, often covered with a special coating, must be wear-resistant to ensure long-term use without deterioration. The design of the wheel also takes into account the requirements for ease of assembly and disassembly, which is important when organizing competitions where quick and efficient adaptation of infrastructure is required.

- Throwing wheels must be designed for adaptation to different climatic and locational conditions. The materials used in their production, such as galvanized steel, guarantee resistance to corrosion and weathering, which is especially important for use in open stadiums. In addition, the design of throwing wheels must be thought out so that they can be easily moved and installed in different locations, which facilitates the organization of competitions and training sessions in different locations.

- The use of throwing wheels in professional competitions requires meeting certain technical standards. Products must be certified by the relevant institutions, which confirms their compliance with the requirements for size, materials and design. Certification is a guarantee that a throwing wheel is properly suited for use in top-level competitions, ensuring that athletes compete equally and fairly.

- A properly designed and manufactured throwing wheel has a direct impact on sports performance. With a stable and smooth surface, athletes can focus on their throwing technique and strength, minimizing the risk of errors due to inadequate starting conditions. Top-quality throwing wheels support athletes in achieving new records and reaching their full potential, so they are an added value to any sports facility.

We encourage you to browse our range of throwing wheels or contact us so that we can choose the most suitable and adequate model to suit your needs.